Umshini Wokufaka Kashokoledi Ozenzakalelayo

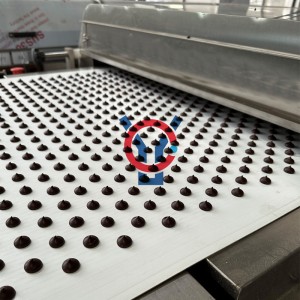

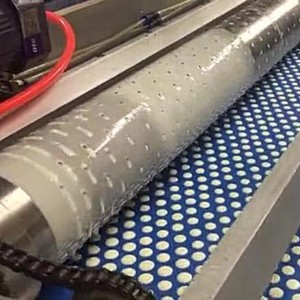

Umshini Wokudipha Ushokoledi /Umshini Wokufaka Ushokoledi Chipsiyisisetshenziswa esizinikele sokukhiqiza ama-chips kashokoledi asesimweni esincane seconsi noma inkinobho. Ingasetshenziselwa ukufaka ama-pastes kashokoledi ngokufaka ikhanda ebhandeni lokuthutha le-PU futhi ilethe imikhiqizo emhubheni wokupholisa ukuze uphole phansi futhi uchithe ngokuzenzakalelayo.Umshini Wokwenza I-Chocolate Chip unezinzuzo zokubeka inani elinembile, ukusebenza okulula kanye nomthamo omkhulu wokukhiqiza. Isikhunta somshini wokwenza amaconsi kashokoledi iyinsimbi engagqwali noma ipulasitiki ye-polycarbonate, ipulasitiki ye-polycarbonate inamandla amahle kakhulu nobulukhuni, kanye nomthamo wokushisa othize kanye ne-thermal conductivity ye-polycarbonate iyafana nekashokoledi, futhi inokusebenza okungcono kokudiliza. Ngaphezu kokusetshenziswa kwalolu hlobo lwepuleti yesikhunta, ukusetshenziswa okwengeziwe kwepuleti le-porcelain, ngoba linokumadlabha okuhle kakhulu nezici ezinhle zokudiliza. Kunezindlela ezimbili zokukhiqiza ama-chocolate chips. Enye indlela i-Pneumatic depositor noma i-servo motor depositor, enye indlela umshini wokwenza ama-chips.

| Imodeli

Imingcele Yezobuchwepheshe | 400 | 600 | 800 | 1000 | 1200 |

| Ububanzi Bebhande Lokuthutha (mm) | 400 | 600 | 800 | 1000 | 1200 |

| Isivinini Sokufaka (izikhathi/umzuzu) | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Isisindo Sokwehla Okukodwa (g) | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 |

| Izinga Lokushisa Lomhubhe Okupholisa(°C) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Ubude bomshini (m) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

I-Chocolate Chip Depositor ivumela ukufakwa kwediphozithi kashokoledi kanye namaconsi enhlanganisela kashokoledi nama-chips ezinhlobonhlobo zomumo nezisindo, kusukela ku-0.1 kuya ku-5 amagremu. Lezi zinhlobo zemikhiqizo zilungele ukuhlinzekwa kwezimboni kanye nokuncibilika okulandelayo, ukuhlobisa kanye nokusetshenziswa kweminye imikhiqizo, ikakhulukazi amakhukhi nama-ayisikhilimu.

I-Chip Depositor Line ihlanganisa ikhanda elifakwe amajakhethi amabili elifakwe ukulawula izinga lokushisa kanye ne-fixed-speed agitator. Ukunyakaza kwekhanda kuhlanganiswa nebhande elisetshenziselwa ukuqoqa imikhiqizo efakiwe. Ulayini futhi uhlanganisa isistimu yokuphakamisa ibhande yediphozi evumela ukuhlukana okuhlukile komumo. Amaconsi adluliselwa emhubheni wokupholisa ngokushesha ngemva kwediphozithi.

Amapiston ediphozithi alawulwa yi-Servo noma Aqhutshwa yi-Pneumatic-Driven athuthukise ukunemba kokulinganisa. I-Optimum tank size kanye nesistimu yokuzungeza amanzi enamajakhethi amabili ukuze kulawulwe kahle amazinga okushisa ediphozithi. Kulula ukususa nokuhlanza i-agitator kashokoledi nethangi. Insimbi engagqwali esetshenziselwa izingxenye zokusebenza nazo zonke izingxenye ezihlangana nomkhiqizo. Isikrini esisebenziseka kalula esine-PLC eklanywe ngokukhethekile silawula yonke imingcele yokusebenza.

Lo mshini oguquguqukayo ungashintshwa kalula ukuze uhlangabezane nezidingo zemikhiqizo emisha, kokubili ngokuya ngedizayini kanye nezinguquko zomumo noma isisindo, ngokumane umiselele ibhodi labasabalalisi, inqubo ethatha imizuzu ukuyiqeda. Itholakala ezinhlobonhlobo zobubanzi bebhande, kusukela ku-400 kuya ku-1200mm.